One of the most powerful ways you can improve the reliability of your plant is by implementing an effective Defect Elimination program. But what does this look like? And where should you start? How do you start eliminating defects?

In this article, I’ll briefly touch on the value of eliminating defects. I’ll also explore the two main approaches to defect elimination process and where they should be used.

Defect Elimination Program

Defects are often thought of as “anything that erodes value, reduces production, compromises health, safety, and environment (HSE), or creates waste.”

This definition comes from Winston Ledet, who in many ways was the founder of the field of defect elimination with his groundbreaking work for Du Pont that later lead to the Manufacturing Game and his books like Don’t Just Fix It, Improve It!

Remember, defects aren’t just physical problems or equipment failures.

They’re the small, niggly problems that cause repetitive breakdowns, lead to safety hazards, and hurt morale.

Defects can come from equipment design, installation, raw materials, workmanship, quality issues, and of course human error.

The defect elimination process is all about ‘fixing forever’ rather than ‘forever fixing’.

It’s about getting rid of the many small problems in your plant so that they never show up again.

Do sweat the small stuff

Lots of companies have a bad actor program.

They use them to target the big reliability hits.

You know, the ones that cause major production issues.

The ones that lead to downtime.

The ones that everyone talks about.

Bad actors typically make up 80% of your losses, but they’re usually only caused by a small amount of the equipment in your plant. From what I’ve seen it’s often even worse than the 80/20 Pareto Principle in that 5% to 10% of equipment issues typically cause 80% of your losses.

And typically all the focus goes to what causes the 80% of your losses.

So, what about the other 20%?

The losses that don’t get all the attention?

The thing is this: these are typically caused by a large number of minor issues, but put together they do add up to big numbers.

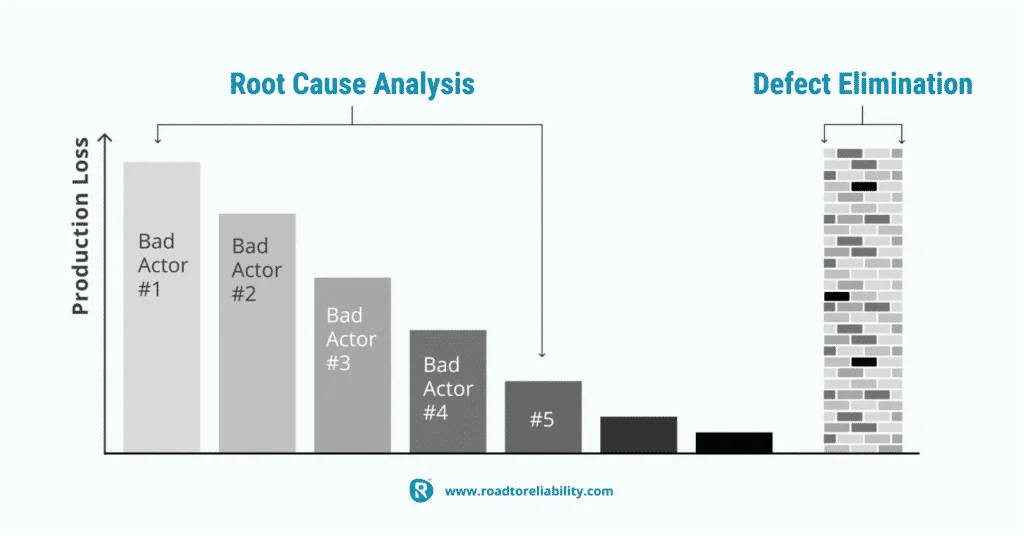

You can see what I mean in this chart (based on the original graphic from TMG Frontline Solutions LLC1):

The big problem areas represent your bad actors.

Plants often take a targeted approach to resolving these issues.

They put a team of engineers on them, and track progress on a monthly or annual basis.

These teams will use advanced Root Cause Analysis techniques and maybe venture into detailed engineering design changes, reliability centred maintenance (RCM)

But just as important are all the little defects (bricks) on the right side.

Eliminating defects like these won’t take much effort. And they can usually be done by smaller teams.

What if you had 10, 20 or 50 small teams each working on a brick at the same time? The results would add up pretty quickly.

So when it comes to the defect elimination process, remember to sweat the small stuff.

That’s the goal.

The wins and the value come from the small stuff.

Top-down & Bottom-up Defect Elimination Program

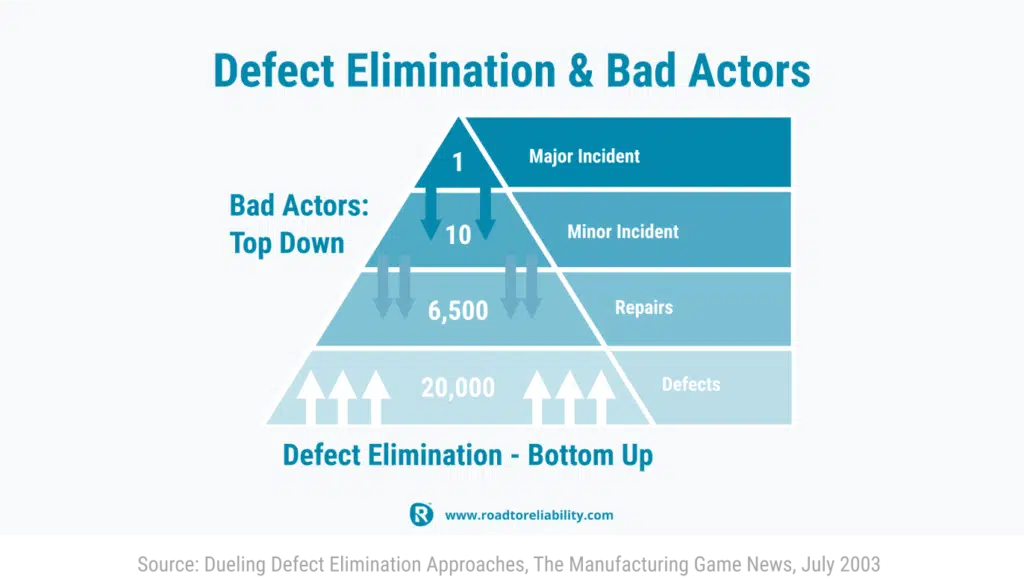

Similar to the original safety pyramid developed by Herbert W. Heinrich in 1931, Winston Ledet developed a defect pyramid2 a version which you see below:

On the safety side, Heinrich’s work tells us that hundreds of minor incidents form the base for dozens of bigger issues.

These bigger issues eventually lead to serious injury.

Similarly, Ledet’s work suggests that tens of thousands of defects lead to thousands of repairs, multiple losses, and eventually, a major incident.

So how do we manage thousands of defects?

We can take two approaches: top-down and bottom-up.

An effective defect elimination process uses both.

It creates a culture that becomes obsessed with not only eliminating defects but also preventing them.

Let’s look at each approach more closely.

Top-down Defect Elimination Program = Root Cause Analysis (RCA)

The first way to eliminating defects is top-down.

As the name suggests, this method is driven by upper management.

It involves very focused teams, and it’s often limited to engineers and select maintenance technicians and operators, who were either involved in the incident or have a strong working knowledge of the equipment.

Top-down defect elimination follows a highly structured approach.

It’s what you use when a catastrophic failure has already occurred. (You know—the one that everyone hears about.)

This is where you’d see a formal root cause analysis process.

Something’s already happened (failed), and now it’s time to figure out why and to prevent reoccurrence.

An effective root cause analysis process uses the following principles:

- Identify bad actors. The bad actors in your plant need to come from what matters most. This might include metrics like downtime, maintenance costs, production losses, trip frequency, maintenance effort including corrective maintenance (CM) + preventive maintenance (PM), etc.

- Prioritise the work. Use Pareto’s Principle to find the select few pieces of equipment that are causing the majority of your losses. Choose the projects that are going to bring the most value (i.e., the best return on investment).

- Define the problem. We’ll never reach the true root cause if we don’t frame the problem properly. This includes validating the problem statement and gathering evidence.

- Analyse and identify causal factors. To really get down to root cause, we need to accept that there might be multiple root causes, human error, systemic issues, and more. We need to go beyond the physical issues.

- Identify possible corrective actions/mitigations. Do we understand the failure modes and patterns? What actions could we take? How do the costs of the actions compare to the costs of the failure?

- Present and approve recommendations. We generally want one action per failure mode. And remember that we always need to be thinking of the value of our efforts. Don’t create new PM tasks just for the sake of it.

- Execute actions. Don’t just make recommendations and let them sit there on a piece of paper or a spreadsheet. Get the changes into your computerised maintenance management system (CMMS) so that the work actually happens in the field, and all your efforts aren’t wasted.

- Track the impact. Monitor the impact of the changes over 6, 12 and 24 months to confirm the problem has indeed been eliminated, and to capture the benefit of the root cause analysis (RCA) process (e.g., convert your uptime to a $ benefit). If things haven’t improved, this is the time to investigate why and make changes.

Let’s look at the alternative approach next: bottom-up defect elimination.

Bottom-up Defect Elimination Program

While top-down defect elimination is driven by management, bottom-up defect elimination comes from the frontline workers who know the equipment the best—your operators and your maintenance technicians.

A bottom-up approach the second way to eliminating defects. It is much more flexible. It isn’t governed by a formal structure or a rigid process.

In that sense, it’s very hands-off with respect to management.

Teams are encouraged to find and eliminate defects that have meaning to them.

This helps with buy-in and ownership. It gives each project a better chance of success.

After all, change happens more easily when people care about the outcome.

The bottom-up approach also differs from top-down in the scale and timing.

Top-down approaches, especially if linked to RCM, tend to be expensive and time-consuming.

In comparison, the bottom-up approach targets short, quick wins.

Each project should take less than three months to complete, and cost no more than a couple thousand dollars (if anything).

The value of the bottom-up approach comes from a lot of small gains, and a high degree of ownership across the company.

Implementing Defect Elimination is a Process

So Bottom-Up defect elimination is all about eliminating small, repetitive reactive work before it happens, and in such a way that it won’t happen again.

Remember, ‘fixed forever’ instead of ‘forever fixing’.

But for DE to work, you need to have a structured process in place.

Now, this doesn’t mean you need a really formal system that is cumbersome and painful.

Quite the opposite.

You need a system that encourages your frontline employees to find and remove defects at the source.

An effective defect elimination process will include the following:

- Multidiscipline action teams: Operators and maintenance technicians as a minimum. Engineers, inspectors, planners, schedulers, and HSE reps might also be on the team.

- Training: Teams need to understand what familiar modes are, and they need to be familiar with the six failure patterns. They should also be taught the concept of mistake-proofing. Your operators should know basic condition monitoring techniques, and your maintenance techs should be trained in precision maintenance if they haven’t been already.

- Identification: Defects can be found in several ways. First, you can use the expertise of your frontline workers to tell you what defects are out there. Second, you can analyse the failure data in your computerised maintenance management system (CMMS). You can also conduct more formal reliability analyses, but then you are no longer in the realms of bottom-up Defect Elimination and more in the top-down approach.

- Tracking: Whatever defects you find should be captured somewhere. This could be in your CMMS or a different system.

- Selection: If you want teams to take ownership of defects, let them choose which defects to work on. There can still be some rules or guidelines in place, but people who have a passion for something will be much more likely to follow it through.

- Resolution: Teams should work through a root cause analysis of some sorts (e.g., five whys, fault tree) to ensure they’re getting to the bottom of the defect.

- Authority: It’s critical that the elimination of a defect does not violate any HSE policy, so you’ll want to have some rules in place around design changes. After all, we don’t want people to introduce new HSE hazards! On the other hand, teams need to feel like they have the authority to fix issues on their own. One way to do this is by setting up a budget they can tap into without a cumbersome approval process. That said, you’ll still want some limits in place for larger sums of money (this could be in the form of a management approval).

- Reporting: It’s important to capture program successes and lessons learned. This doesn’t just mean counting the number of defects eliminated. You should also look at savings, and trend the changes in all other areas of the plant over time (reactive work, planned work as a percentage of total maintenance, safety incidents, etc.).

Defect Elimination Process With The 1% Rule

If you’re still not sure where to start, try the 1% rule, as coined by Winston Ledet.

Winston and his team ran a computer model, which showed that if you turn 1 out of every 100 work orders into a defect elimination order, you can reduce your work order count by 37.5% over three years. If you keep this up for eight years, the work orders are reduced by 70%. These numbers were verified using data from a refinery in Lima, Ohio (one of the plants that inspired Don’t Just Fix It, Improve It).

And remember, DE does not have to focus on just physical improvements.

Defects are mostly from careless work habits, so improving work practices can be hugely beneficial and result in big leverage (i.e., they apply to lots of equipment).

Putting Limitations on Defect Elimination

While the defect elimination process can work wonders, we still must remember that in complex, hazardous plants, change needs to be managed carefully.

Yes, we want to encourage ownership and a certain degree of autonomy.

BUT—and this is a big one—we can’t have people making unauthorised modifications that could have personal and process safety implications.

You need to have some sort of a screening step in place to ensure that all HSE risks are considered.

This might mean that you have to use a more formalised change management process to truly eliminate some defects.

And that’s okay.

An important part of the defect elimination mindset is defect prevention.

Defect Elimination Culture

Defect Elimination is a culture.

If an organisation wants to successfully start and sustain a defect elimination program, it has to get buy-in from everyone.

And I mean everyone.

From the C-suite to the frontline maintenance technicians to procurement, and everyone in between.

Defect elimination needs to be thought of as everyone’s responsibility, much like safety and reliability. There should be a defect elimination culture in your organisation.

A culture that supports defect elimination is also one that supports defect prevention.

It encourages employees at all levels and departments to be mindful of where and how defects could be introduced throughout the life cycle of a piece of equipment.

And it gives frontline workers the authority and confidence to tackle the small issues that not only matter to them but also to the company’s bottom line.

Final Thoughts

An effective defect elimination program requires a structured approach. You should see it as a process, as well as a reflection of your culture, and mindset.

Eliminating defects will require a combination of a top-down approach and a bottom-up approach. The top-down approach is your traditional root cause analysis approach reserved for your big issues, your bad actors.

The bottom-up approach is where you let small teams of your front-line workers loose to deal with the many small, niggly issues that when combined over time will cause a lot of loss and waste. This is where you deploy the 1% Rule.

When combined with the other basics of planning & scheduling and preventive maintenance, a defect elimination program will have a profound impact on your plant’s reliability and performance.

[2] Slide courtesy of The RM Group Inc., Knoxville, TN. Based on the work of Winston Ledet, The Manufacturing Game®, Ledet Enterprises Inc., Humble, TX