What is Predictive Maintenance?

When people talk about predictive maintenance, it is often used as a synonym for condition-based maintenance. But in my view, with the advent of artificial

Read our short, to the point, practical ‘Reliability Insights’ and delve deeper into a topic with our in-depth, actionable ‘Articles’

When people talk about predictive maintenance, it is often used as a synonym for condition-based maintenance. But in my view, with the advent of artificial

When you read about maintenance strategies on the web, there seems to be a belief or confusion that maintenance strategies and maintenance types are the

Many organisations are stuck and seeking ways to escape reactive maintenance, as they face a ‘vicious cycle of urgent fixes It’s an all-too-common situation. Once

Delve deeper into a topic with our In-Depth Articles that provide action knowledge:

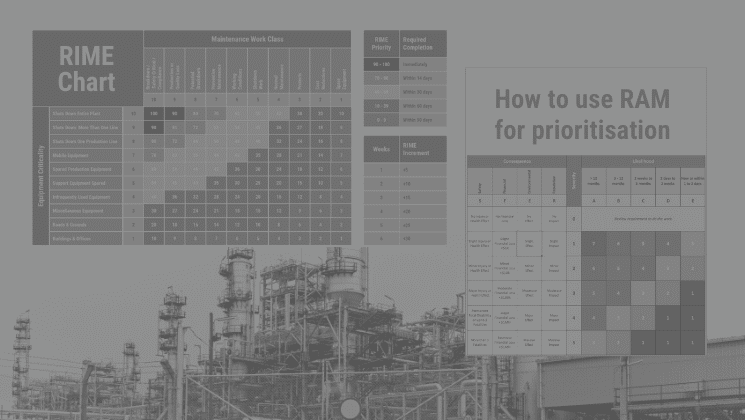

Maintenance Planning & Scheduling (MPS) is one of the key elements of a reliable plant. When done right, it increases your workforce productivity by at

An effective PM program uses a mix of different types of maintenance, and that includes corrective maintenance. As we will see in the rest of

There’s a big difference between busy and productive. A lot of times, maintenance technicians are busy juggling hundreds of tasks in a day. They’re busy

Contact Us:

Call in Australia: 1 800 312 402

Call from overseas: +61 2 836 626 74

Email: [email protected]

Address:

Level 14, 167 Eagle Street

Brisbane, QLD 4000

Australia

© 2017-2023 R2 Reliability Pty Ltd.

All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings

© 2017-2023 R2 Reliability Pty Ltd.

All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings