Without planning and scheduling you will fail

Maintenance Planning & Scheduling is one of the 4 Essential Elements on the Road to Reliability™. Planning & scheduling, or work management as it’s often called, ensures the right work gets done, at the right time, with the right tools, materials, and people. Without an effective maintenance planning & scheduling process, you’ll never achieve high […]

Escaping the Vicious Cycle of Reactive Maintenance: The 4 Essential Steps on the Road to Reliability

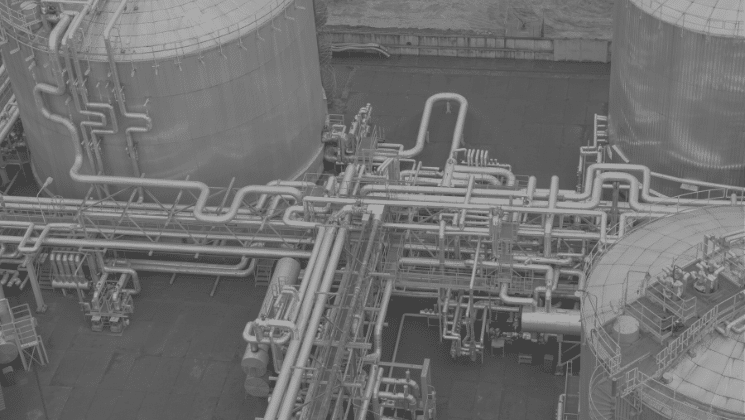

Most industrial plants around the world are trapped in the vicious cycle of reactive maintenance. These plants and their teams silently suffer from low reliability, high maintenance costs, low morale, and too much stress. Unfortunately, the journey to create a Reliable Plant has been made unnecessarily complex. In this article, I will show you how […]

3 Simple Steps to Escaping the Vicious Cycle of Reactive Maintenance

Many organisations are stuck in a ‘vicious cycle of reactive maintenance’. It’s an all-too-common situation. Once you finally get that emergency fixed and resolved… you find yourself looking at 10 more emergencies that you need to deal with. And being ‘emergencies’, there is no time to plan. No time to schedule. Forget about staging and […]

Why standardising your process is a crucial first step before automation

Many of our tasks are automated. But just imagine that you need to manually do some of those. For example, collect and process data from different areas of your plant. That would be a nightmare. And one would think it as a waste of time. But someone’s got to do it, right? That’s why automation […]

The Waddington Effect

Is doing more maintenance ‘good’? It’s common to think so. I mean, it makes sense that the more maintenance you do… the less likely your equipment is to fail. Right? But if that’s the case… Why do we still suffer from poor reliability? Why do we still struggle with emergency breakdowns? Why do we struggle with expensive […]

How to stay reliable DESPITE maintenance budget cuts

How’s your maintenance budget? Chances are you think it’s not enough. And you resent that it’s been cut back for the umpteenth time. Every organisation should have the necessary budget to execute the required maintenance. But that’s often not the case, so… “How do you stay reliable despite numerous maintenance budget cuts?” Now, this is […]

Why do we reward poor behaviour?

When it comes to building a culture of reliability, what you say is important. What you do is even more important. But what you reward is KEY to your success. And we want nothing more than to reward good behaviour and good employees. See, people must feel valued and committed to their work to sustain […]

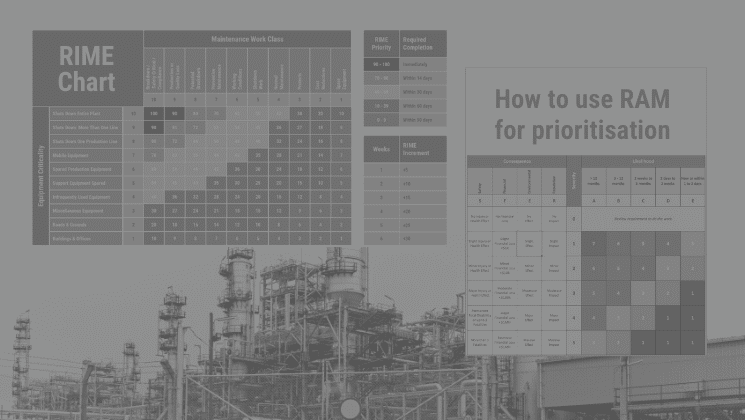

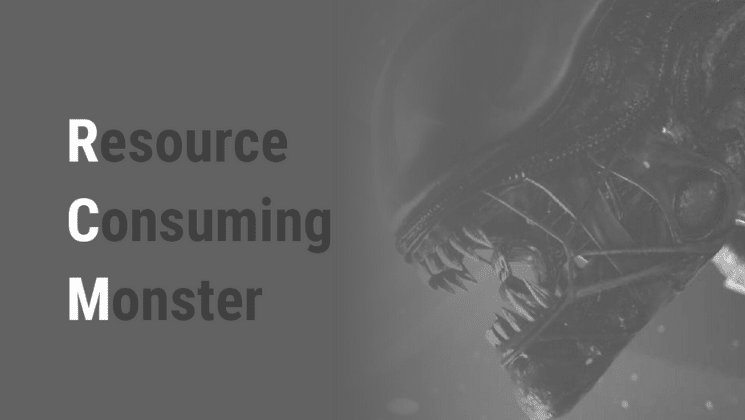

RCM’s bad reputation

Improving reliability has always been the top priority of many maintenance managers and practitioners. And so as an industry, we’ve come up with numerous strategies to help us achieve that goal. One notable strategy that has created hype in the maintenance world is Reliability Centered Maintenance (RCM). See, everybody wants to join the RCM bandwagon […]

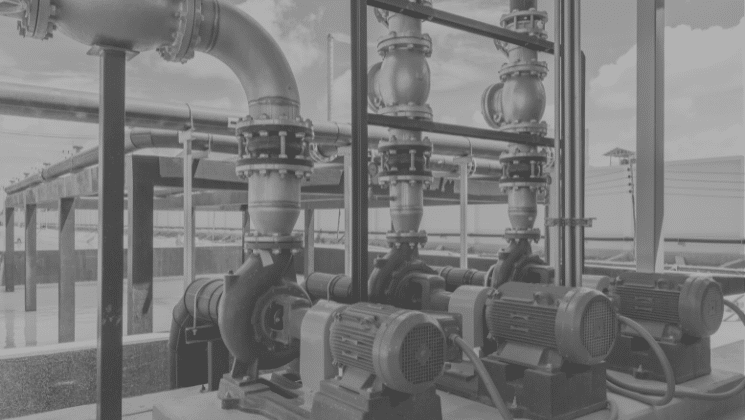

Your CBM Efforts Will Fail Without Effective Planning & Scheduling

This article first appeared in reliable plant. You can read the first version of this article here. Many maintenance organisations around the world are reactive. They experience excessive breakdowns, low productivity, and high maintenance costs. To break this reactive cycle, a common solution organisations implement is Condition-Based Maintenance. The problem is this strategy rarely works. […]

Root Cause Failure Analysis Using The 5 Whys Method

As maintenance practitioners, we’ve all have heard about the 5 Whys. And chances are, many of us have used this approach to execute Root Cause Failure Analysis at some point in your career. While it may seem like a simple and easy-to-use tool to look for root causes, you need to approach the 5 Whys […]