As I discussed in the article, “9 Principles of Effective PM Programs based on Reliability Centered Maintenance (RCM)”, most failure modes are not age related. Instead, they experience a constant rate of failure. And the way to manage these types of failures modes is through condition based maintenance (CBM). That is why most preventive maintenance programs out there should be composed mostly of CBM.

Unfortunately, many plants around the world do not follow this principle. Instead, they are filled with time-based maintenance tasks despite having failure modes that are not age-related. Clearly, there’s a disconnect. That’s why in this article, I want to shed light on what condition based maintenance is all about. And we’ll dive into a few examples of how it is used in industry.

Key Takeaways:

- The majority of your PM program should be condition based maintenance because most failure modes are not age-related. Instead, they are subject to random failures.

- There are many forms of condition-based maintenance and they do not all require advanced technology or online condition monitoring. Condition based maintenance does not necessarily mean fancy expensive technology. Condition based maintenance can come in many forms and can consist of using simple approaches and simple inexpensive tools.

- To run effective condition-based maintenance, you need to have an effective planning and scheduling process in place. Because if you don’t and you’re in the midst of a reactive maintenance environment, the early warnings this condition-based maintenance program gives you will simply be lost and you will be wasting your time and money.

- Don’t start a condition monitoring program unless you actually have an effective planning and scheduling program in place so that you can deal with the alerts that come from your condition-based maintenance program in a timely fashion.

What is Condition-based Maintenance?

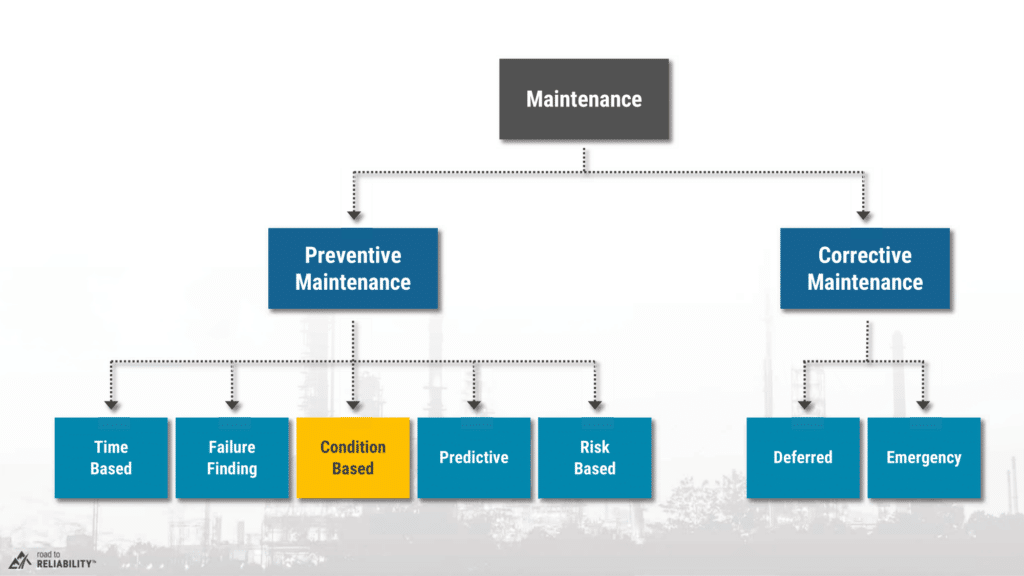

Now, as I discussed in the article, “The 9 Types of Maintenance: How to Choose the Right Maintenance Strategy“, condition based maintenance is a form of preventive maintenance in that it’s a type of maintenance we’re doing before failure has occurred.

We use condition-based maintenance to see if a potential failure mode is developing by measuring, monitoring, and trending a specific condition. Remember, most failure modes are not age-related. However, most of them give you some sort of warning that they are in the process of occurring or about to occur.

Condition based maintenance therefore looks for physical evidence of these warnings. It’s important to realise that condition based maintenance does not reduce the likelihood of the failure occurring. Instead, condition based maintenance aims to give you information about impending failures, so that you can intervene before they occur on the premise that it is more economical.

Now, when dealing with condition based maintenance, you need to assess the condition of your asset based on a series of measurements of selected parameters made over a period of time.

Examples of Condition Monitoring Parameters

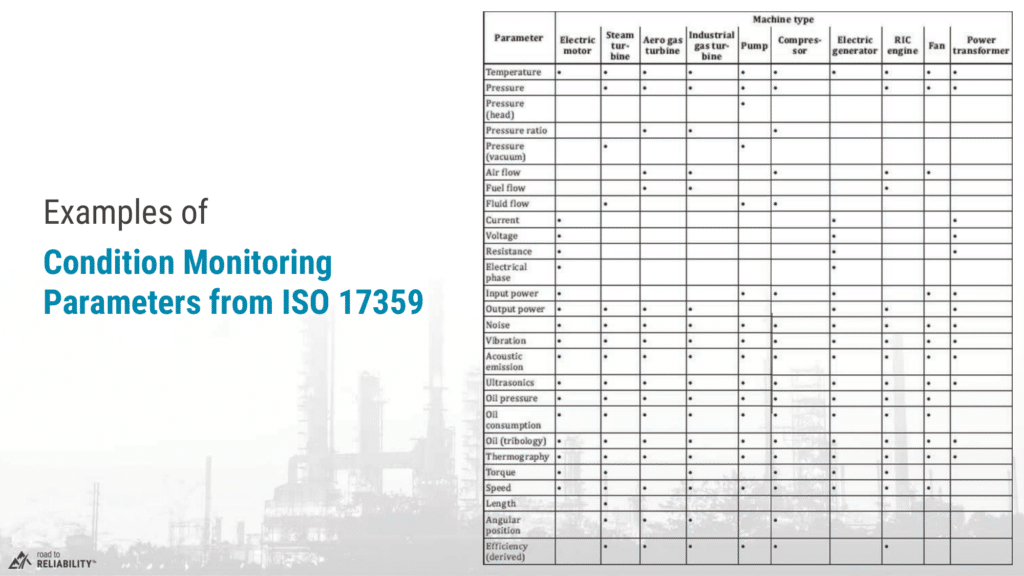

There are literally dozens of parameters that we could monitor for our condition monitoring. What we analyse depends on the equipment we’re dealing with, as well as the failure modes we’re concerned about. All of which, will be influenced by your operating context.

Now, what I’m showing here is a list of potential condition monitoring examples from ISO Standard 17359. I’ll discuss a few parameters listed here later in the article. Of course, you can’t blindly follow these tables. You need to do your own analysis. But it will certainly give you a good starting point of what condition monitoring parameters and techniques you may be able to use for your plant and equipment.

Bear in mind that condition monitoring and condition-based maintenance is a rapidly moving field due to fast-moving advances in technology. Not everything will be listed in the ISO standard either, and it is always good to go out there in the market and see what is available

The P-F Curve

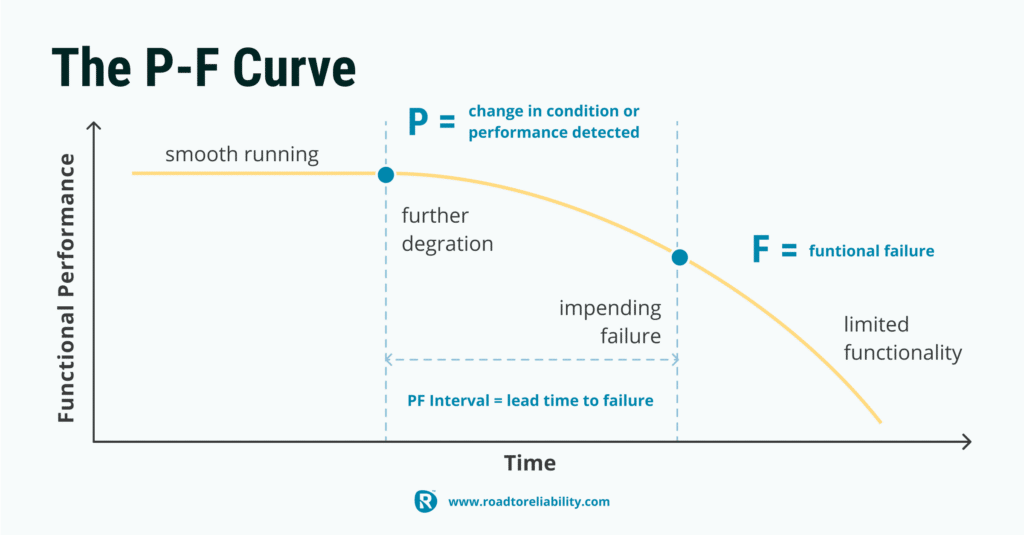

An important concept within Condition Based Maintenance is the P-F curve shown in the figure below:

The curve shows that as a failure starts manifesting, the equipment deteriorates to a point at which it can be detected (point “P”). If the failure is not detected and mitigated, it continues until a functional failure occurs (point “F”). The time range between P and F, commonly called the P-F interval, is the window of opportunity for you to detect the imminent failure and address it.

A common rule of thumb is that the interval between CBM tasks should be one-half or one-third of the P-F interval. How much more effective condition based maintenance is compared to breakdown maintenance depends on how long the P-F interval is.

Lead time for Condition Monitoring Techniques

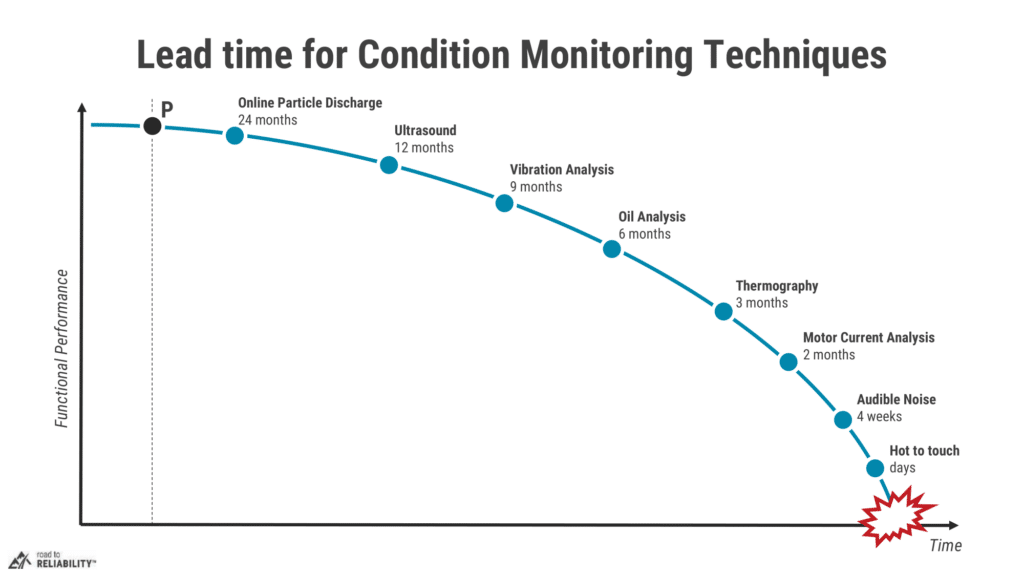

This is where the selection of your condition based maintenance technologies come into play. When you surf the web and you read various articles on condition-based maintenance, you’re going to encounter diagrams like you see here. A P-F curve where various condition monitoring technologies are plotted with an indicative lead time.

The black point at the top left of the curve, point P, is the point at which the failure in essence starts to develop. The blue points along this curve are indications of how early you could detect that developing failure mode using different condition monitoring techniques. You can see that with vibration analysis, you could potentially detect the failure up to nine months ahead. With lube oil analysis, maybe six months ahead.

But curves like these can be misleading because the lead time depends not just in the technique you’re using, but also the failure mode you’re looking for. Of course, it also depends on how well you are applying that condition monitoring technique, what technology you’re using, and what tools you’re using.

For example, thermography might only give you three months lead time on a bearing failure, but when applied to electrical failure modes, thermography might give you much longer lead times. You need to consider these curves more as a concept, and not much more. Unless of course the P-F curve you’re looking at is specific for a failure mode.

Common Condition Monitoring Technologies

Now, in the rest of this article, I’m going to talk about some of the most common condition monitoring technologies used in industry. Things like vibration analysis, oil analysis, thermography, and ultrasound. For each of these, I’m going to give a summary of the technique and I’m going to include some potential applications. So make sure to download the list of potential condition monitoring examples so you can use it as a reference.

Vibration Analysis

Vibration analysis forms the core of almost all condition monitoring programs. It’s non-intrusive and it provides instant results. Anytime a piece of machinery is running, it’s creating vibrations. An accelerometer is attached to the machine and it generates a voltage signal that corresponds to the amount of vibration and the frequency of the vibration that the machine is producing.

Analyzing that vibration can then be used to detect issues like imbalance, and bearing failures, mechanical looseness, misalignment, and a whole range of potential faults and failure modes. It’s been estimated that vibration analysis can give you lead times up to nine months before a failure occurs with some of these failure modes. But that depends on the failure mode, your detection methods, your operating context, the equipment, and a lot more.

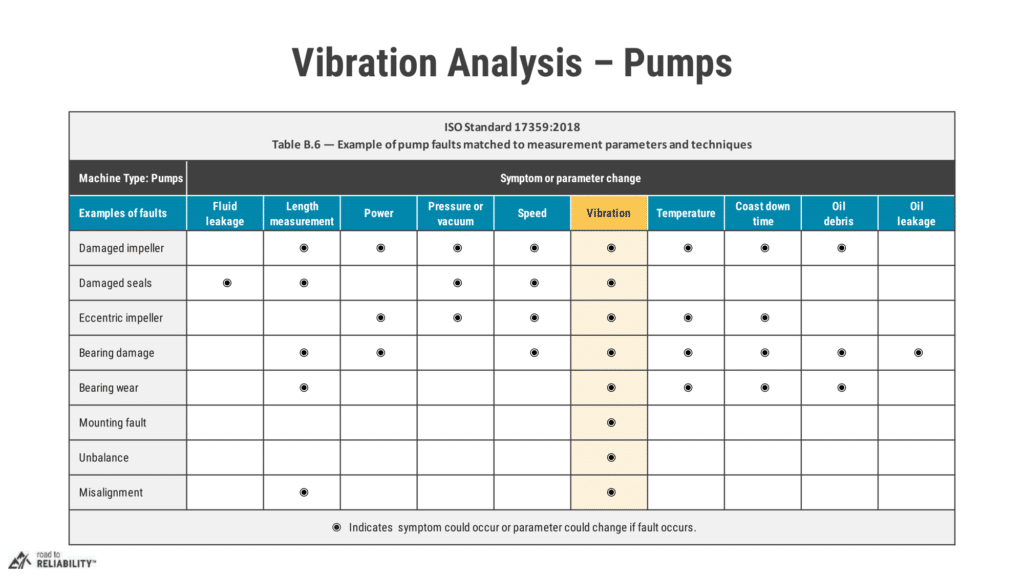

Now, this is a table that shows potential condition monitoring parameters that you can use to diagnose failure modes relating to centrifugal pumps.

As you can see, I’ve highlighted here the column of vibration because we’re talking about vibration analysis. It shows that with vibration monitoring, you can detect a wide range of issues on centrifugal pumps from damaged impellers to damaged bearings, mounting issues, or misalignment.

Lube Oil Analysis

Another widely used condition monitoring practice is lube oil analysis. Unlike vibration monitoring, lube oil analysis is intrusive in the sense that you have to access the system and take a sample out. It is not instant in the sense that the sample needs to be analyzed and very often that’s done by sending it away to a specialized lab.

Now lube oil analysis is used to analyze the health of your lubricants. You’re checking the oil for contamination and you’re determining if your equipment is exhibiting wear. Simply said, you perform lube oil analysis to understand the condition of the oil you have, and the condition of the machine from which the oil was taken. Typically, when you do lube oil analysis, you look at three main categories of analysis. Fluid properties, contamination, and wear debris.

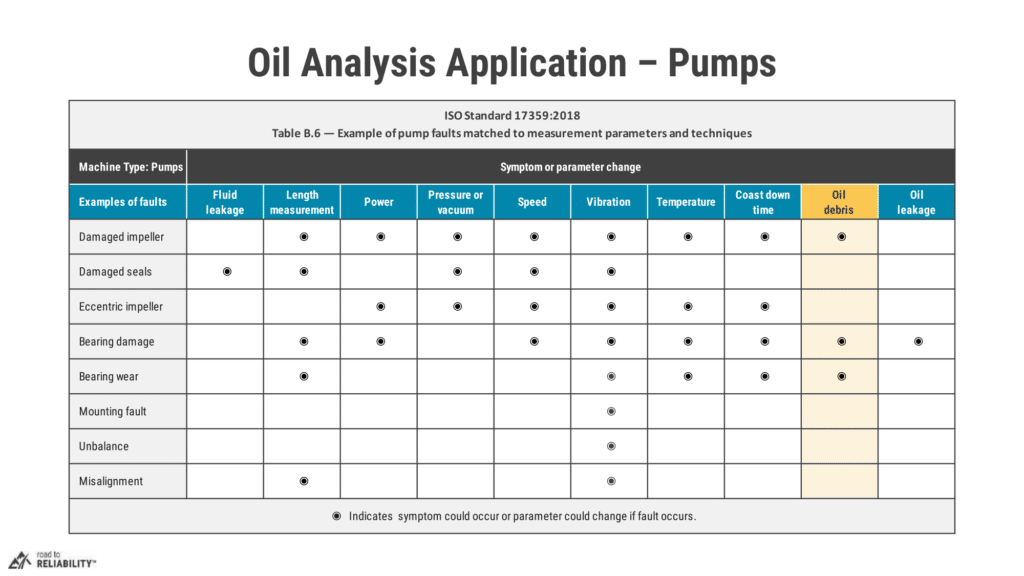

Now, looking at the same chart showing condition monitoring parameters for centrifugal pumps, you can see that we can also use lube oil analysis to determine a number of faults. In this case, we can see that we can use the lube oil analysis looking for wear debris to see if we’re experiencing, say, impeller wear or bearing wear. Once again, that same concept applies to compressors and turbines and other rotating equipment. But lube oil analysis is also very powerful when it comes for example, to other types of equipment like power transformers.

Thermography

Another common condition monitoring technique is thermography. Now thermography provides temperature information. It is non-intrusive and it provides relatively instant results. You can use thermography for comparative measurements, but also for absolute measurements. Thermography, strictly speaking should be called infrared thermography because we’re using infrared thermal imaging to detect heat radiation emitted from an object. Then we convert that to a temperature distribution, which is displayed on top of an actual image.

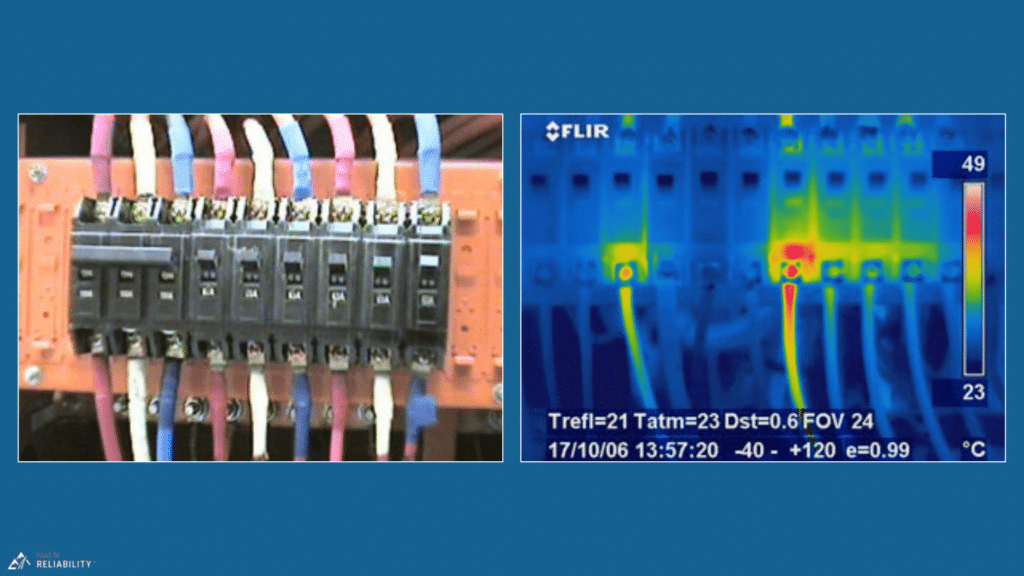

Now, thermography is commonly used to monitor electrical equipment and mechanical conditions of say motors and bearings, refractory insulation, and even locating gas and liquids and sludge levels in vessels. It’s also used for identifying hotspots in electrical systems like switchboards or cable terminations.

This image here actually shows how powerful the concept of thermography is, right. Looking at the picture on the left, you would have no idea which connection was loose, but by using a thermal image on the right, you can very quickly determine which terminals are the issue. It is a quick, safe, and nowadays relatively cheap technology. That images you see here show storage vessels in oil and gas applications.

Ultrasound

Ultrasound is another condition monitoring technique that is maybe less well-known, but it has grown a lot in recent years. Ultrasound relies on the detection of signals that are well above the range of the human hearing, i.e. they’re well above 20 kilohertz.

These signals are therefore detected either with airborne microphones or using contact microphones. Ultrasound testing is very useful for low and high-speed mechanical applications and high-pressure fluid situations.

For example, a digital ultrasonic media can be used to measure high frequency signals from bearings. Then over time, this can be used to create a historical trend to predict increases in friction, rubbing, or other bearing defects. It can then also be used to predict proper lubrication intervals for those bearings.

What you see in the other picture here is an ultrasonic grease gun, which are quite common nowadays. They basically allow you to dispense the required amount of grease based on condition rather than a fixed amount, so you typically get a much better result.

Requirements for Effective Condition based Maintenance

There are few things you need to effectively implement condition based maintenance in your organisation:

- A clear understanding of the failure modes you’re dealing with and a good insight into the associated parameters that need to be monitored.

- You then need to make sure that you actually have a relatively consistent P-F interval so that you have a repeatable and predictable process.

- You need to make sure that you have knowledge and the understanding to analyze the results and recommend appropriate corrective actions.

- You also need to have the ability to execute those corrective actions in a timely manner. Otherwise, all your efforts in the condition-based maintenance program will simply go to waste.

Lastly, a piece of advice, start small, keep it simple, focus on the value condition-based maintenance can deliver for your organization, and you can build a successful program.

Planning & Scheduling Before Condition-based Maintenance

We’ve established that condition based maintenance lets us know of impending failures ahead of time. But when you’re working in a highly reactive maintenance environment, chances are you’re too busy dealing with emergencies to address the issues brought about by your CBM.

This is why you need to implement planning & scheduling BEFORE condition-based maintenance. With plenty of warning, the rectification can be planned, materials and resources can be mobilized, and breakdown prevented. But when your P-F interval is only a few days, the resulting actions are much like a breakdown and the value of CBM is largely lost.

For CBM to be effective, early intervention is essential. This requires an efficient and effective process for data gathering, data analysis, decision making, and finally intervention. So, don’t start a condition monitoring program unless you actually have an effective planning and scheduling program in place so that you can deal with the alerts that come from your condition-based maintenance program in a timely fashion.

Condition based maintenance is more than technology

So far, we’ve seen that condition-based maintenance has been strongly driven many different technologies out there. But effective condition-based maintenance relies on much more than just technology. You need to have the right people and practices so that when you apply the technology, you get accurate and repeatable measurements.

You need to have the people who understand what those measurements are telling you, and then are able to translate that into a correct and effective intervention. You then need to make that intervention at the right time. And you need to manage this whole thing as an end-to-end process.

Condition-based maintenance is not just a set of technologies. It needs to be implemented as a business process alongside your maintenance execution process, alongside your planning and scheduling process.

That’s why condition-based maintenance can be relatively low tech too. Take vibration analysis, which is probably one of the most widely used condition-based maintenance techniques. You don’t need complex online monitoring solutions that check your machines 24/7. Simple handheld vibration meters can be bought relatively inexpensively nowadays, and if used well, can make a huge difference. The same goes for infrared cameras, ultrasonic sensors, and other technologies.

Conclusion

Most failure modes out there are not age related. Your PM program can therefore largely benefit from implementing condition-based maintenance. Condition based maintenance is a type of preventive maintenance that looks for physical evidence of early signs of failure. It’s important to realise that condition based maintenance does not reduce the likelihood of the failure occurring. Instead, condition based maintenance aims to give you information about impending failures, so that you can intervene before they occur on the premise that it is more economical.

When dealing with condition based maintenance, you need to assess the condition of your asset based on a series of measurements of selected parameters made over a period of time. Now, there are literally dozens of parameters that we could monitor for our condition monitoring. The most used condition monitoring techniques are vibration analysis, lube oil analysis, thermography, and ultrasound.

Before you implement condition based maintenance, it is important that you first have an effective maintenance planning & scheduling process in place so that you have room to act on the information provided by your CBM technology.

And although many condition based maintenance techniques are heavily focused on technology, effective condition-based maintenance relies on much more than just technology. You need to have the right people and practices so that when you apply the technology, you get accurate and repeatable measurements.