Root Cause Failure Analysis Using The 5 Whys Method

As maintenance practitioners, we’ve all have heard about the 5 Whys. And chances are, many of us have used this approach to execute Root Cause Failure Analysis at some point in your career. While it may seem like a simple and easy-to-use tool to look for root causes, you need to approach the 5 Whys […]

Unlock Leadership Support for Maintenance

Introduction Unlocking leadership support for maintenance and reliability initiatives is a common challenge in our industry. Many maintenance professionals face the uphill task of gaining buy-in from management. “Management doesn’t want to invest in maintenance and reliability”. Does this sound familiar? It’s a common complaint I hear when I talk to maintenance practitioners. Unlocking leadership […]

Risk-Based Criticality: A Time Waster

Introduction Risk-based criticality assessment is often a waste of time. It’s more of an academic exercise than a practical solution. Many people advocate for criticality assessment because you “need to know your critical assets“. When you read articles, books, or LinkedIn posts around reliability, it seems that using criticality is a given. They would say […]

Escaping the Cycle of Reactive Maintenance

Working in a highly reactive maintenance environment is extremely stressful. Imagine being trapped in a never-ending cycle of chaos, where every day brings a new crisis to manage, and you’re constantly trying to figure how to put out fires. This is the reality for many professionals working in a highly reactive maintenance environment. The relentless […]

Maintenance Planners deserve BETTER.

Maintenance Planners are the unsung heroes responsible for increasing your team’s productivity by at least 30%, translating to hundreds of thousands, if not millions, of dollars saved each and every year. Yet, despite the immense value they create, planners are often undervalued, and their role is misunderstood in many organizations. In this article, we’ll dive […]

Master the Basics: Your Key to Tech Success

Diving headfirst into new technology might seem like a good idea at first, especially when it comes to improving your plant’s reliability. But mastering the basics is essential—it’s your key to tech success. When I ask my students and clients what their strategy is for improving their plant’s reliability, two common strategies that often come […]

You can’t maintain your way to reliability

We often hear the phrase “maintenance is key to reliability”. And while it’s true that proper maintenance is important, it’s not the only factor that determines your plant’s reliability. In fact, relying solely on maintenance to ensure reliability can be dangerous to your organisation. In this short article, I’ll explain why that’s the case. Maintenance […]

5 Mistakes in Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is not an easy process to complete. Along the way, you may encounter common mistakes in reliability-centred maintenance or identify things you could do better next time. That’s fine. That’s continuous improvement. But what you don’t want to do is start an RCM study with the common mistakes in Reliability Centered […]

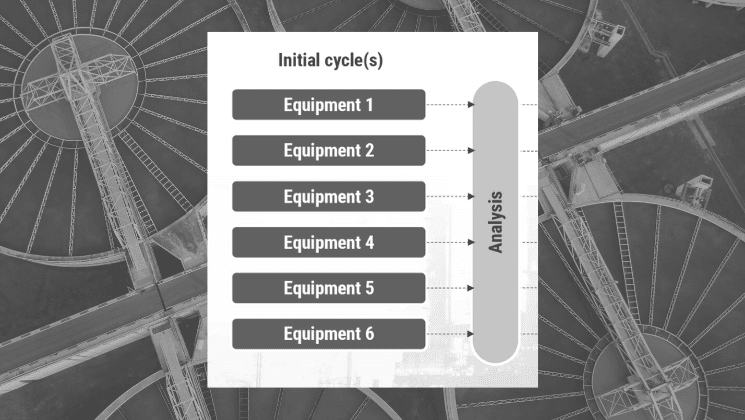

What is Reliability Centered Maintenance?

Have you ever wondered how efficient we can get with our preventive maintenance tasks? Is there some sort of maximum efficiency that only the Gods of maintenance know of? Maybe. But for mortals like us, there is what I call a gold standard that we can strive for. It’s called Reliability Centered Maintenance (RCM). To […]

What is Risk-based Maintenance (RbM)?

As maintenance practitioners, we have a responsibility to maximise our scarce maintenance resources. Especially since maintenance is often subject to tough budget cuts. We need to be as efficient as we can when it comes to our preventive maintenance. That’s why good preventive maintenance programs and maintenance strategies don’t try to fix everything. They are […]