5 steps to manage maintenance backlogs

A lot of people have very fixed ideas about maintenance backlog.

Some people see backlog as any work that was due in the past. Others also include work that is rescheduled for the future (which is technically called forelog).

But I like to make things as simple as possible. In my simple view, backlog is just all outstanding work. All the work that has not yet been done but needs doing. It’s simple, it’s easy to define, and easy to understand.

Now, having a backlog (=outstanding work) is actually a good thing.

Because in most industrial plants, you can’t afford to have maintenance crews sitting around waiting for work to come through.

It’s inefficient.That’s why you need to have a backlog of work.

But let me emphasize this… there must be a REASONABLE amount.

You don’t want months or years of outstanding work, as you’ll soon find yourself in a plant that is no longer safe or reliable.And you don’t want overdue work sitting in your backlog. Based on industry experience, a sensible amount of backlog to aim for is about 6-8 weeks.And that begs the question…

How do you make sure that’s there’s not too much or too little backlog? To effectively manage your backlog… there are 5 steps you need to take.

First, clean up your backlog.

Before you start managing your backlog, you need to resolve work orders that should no longer be there.

Often, when you leave your backlog unmanaged for a long time, it becomes chaotic and filled with work that is…

- Duplicate

- Too unclear to work with

- Not important enough

- So old that the issue has already been resolved

- Already completed but is still sitting in the backlog

- Not suitable for executing through the maintenance process

Resolve these stagnant work orders before you start managing your backlog.

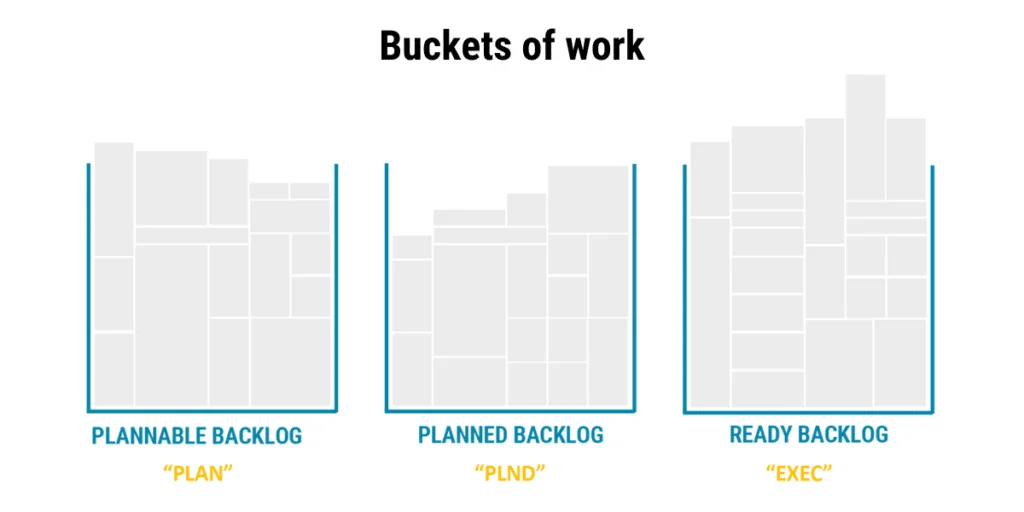

Second, you need to take the backlog that’s left and spread it across different “buckets of work“.

It’s a concept I teach my students where you divide the work into—

- Plannable backlog is the work that still needs to be planned by the planner or is actively being planned. This is the backlog that is clearly owned by the planner.

- Planned backlog is the work that has been fully planned as per the status indicators, but is not yet ready to be executed because either the materials aren’t yet confirmed to be on-site,or the contractor or vendor availability has not been confirmed or special tools or hire equipment has not yet been confirmed.

- Ready backlog are older jobs that are ready to go. They are ready to execute. They can be done whenever the scheduler can fit them into the schedule, as all material and service constraints have been set and met. This backlog is owned by the scheduler.

What’s good about this is, each bucket aligns nicely with a specific step of your planning and scheduling process. So, all the work in that bucket is at the same phase in the overall planning and scheduling process.

That means that if a certain bucket is overflowing, then we have a bottleneck in that step of the planning and scheduling process.

Third, use statuses that separate your outstanding work accordingly in your CMMS.

For example:

For plannable backlog, use something like “PLAN”,

Planned backlog, you can use “PLND”,

And ready to execute backlog could be “EXEC.”

Fourth, you need to set up a regular backlog review meeting.

Start out with a review every two weeks, then see whether it can be less or more frequent.

The objective of the backlog review meeting is to proactively manage the backlog.

You want to agree on…

- the priorities for what needs to be planned next

- which work needs to be ready for the frozen weekly schedule in the following weeks

- required actions if your backlog is continuously growing and moving well beyond the six to eight-week target.

Finally, have your three buckets of backlog broken down into three different views.

The first view is an aging report that shows the amount of work by age, i.e. how much of your outstanding work is, say, 30 days old. How much is 60 days old? How much is 90 days or more?

The second view is by priority. You can use the RIME or RAM approach to help you prioritise which work needs to be done first.

The third view shows all your outstanding work by equipment or by system. This is very helpful when it comes to grouping work and making sure you don’t have unnecessary equipment downtime.

Those are the 5 steps that you need to take to fully and effectively manage your backlog.

To summarise, remember these 3 key points:

- Having a backlog is a good thing. To have an efficient and effective planning & scheduling process you need to have a reasonable amount of backlog. In most industrial plants you really can’t afford to have maintenance crews sitting around waiting for work to come through.

- Although it is good to have backlog, you need to make sure it is a reasonable amount. You don’t want months or years of work outstanding as you’ll soon find yourself in a plant that is no longer safe or reliable. Instead, a sensible amount of backlog to aim for is about 6-8 weeks.

- You need to take that backlog, your outstanding work, and spread it across different buckets of work and actively manage them accordingly. I like to use three different buckets for outstanding work: plannable work, planned work, ready backlog.

If you want to learn how to implement each step effectively, then you can check out our online course where we teach it in greater detail.