After 20+ years in the maintenance & reliability game… I created the ONLY Maintenance Planning and Scheduling online training course that teaches you the theory AND shows you how to implement it

Master Maintenance Planning & Scheduling in 10 Weeks or Less

Use our 6-step maintenance planning & scheduling process to get your team out of the reactive maintenance cycle, increase productivity, demonstrate your value as a true maintenance professional, and finally secure that promotion.

Join our clients from all over the world in their journey to higher reliability

Then I have something important to share with you.

On this page, you’ll discover the ONLY online training course that will teach you how to effectively implement Maintenance Planning & Scheduling using a proven framework.

Through the course, you will…

Within 10 weeks or less, you’ll learn the Maintenance Planning & Scheduling process that took me 20 years to master and develop.

Unlike traditional Maintenance Planning & Scheduling Courses, this is an online and on-demand course where you will have Lifetime Access.

Here’s what my students have to say about the course:

Raymond Chizu

Sales & Business Development Executive, WearCheck Tribology Services, Zimbabwe

“PS100 is the ideal course for anyone in Maintenance (individuals and organizations) who are focused on quality.

The beauty of this course is that every plant out there has the framework of maintenance planning and scheduling in place (already there’s a solid base to start on), all what is left is to implement the 6 elements of planning & scheduling in their correct sequence and apply the 6 principles of both planning & scheduling and see your productivity (wrench time) increase from an average of <30% to a respectable 45% or even go to a world-class figure of >55%.

For anyone who’s tired of firefighting in their maintenance culture, PS100 is the right course”

Vijay Singh

Assistant Plant Manager, Seven Seas, Trinidad and Tobago

The training material provided in this course has been very relevant and the Instructor, Erik Hupje has been able to utilize his industry experience to deliver an exceptional online tutorial.

His reference to poor decision making, planning deficiencies and every other organizational shortcoming in Planning & Scheduling has been a true reflection of my experience.

Felipe Cabrera

Project Manager, Texas, United States

It has to be the best course I have ever taken on Planning and Scheduling.

Thank you for putting it on! I thought I knew Planning and Scheduling; Now I do….

Vinícius Wittig Vianna

Offshore Planning Analyst, MODEC, Brazil

The experience in this training was very productive.

The concepts were explained in details with a operational and strategic view. Many practical exercises were proposed which added a lot in my professional responsibilities related to maintenance planning/scheduling.Let me first introduce myself

Hi, my name is Erik Hupjé, founder of R2 Reliability and developer of the Road to Reliability™ Framework.

For over 20 years, I’ve worked in asset management, specifically in maintenance & reliability in the upstream oil & gas industry. I’ve worked in The Netherlands, the United Kingdom, the Philippines, the Sultanate of Oman, and Australia.

Now, I help hundreds of maintenance professionals like you advance their careers through my courses and coaching programs. On this page, I’ll introduce to you my most popular and most successful course the PS100: Implementing Maintenance Planning & Scheduling.

Before I get into the details…

I want to share with you a bit of my story. If you’ve been struggling with Planning & Scheduling for a while now, then I urge you to continue reading the rest of this page. You see, before I created this course…

I once was a firefighter too

I remember the days when I was constantly running around from one emergency to the next.

I was chasing missing parts. Arguing with operations to get access to equipment. And dealing with unplanned work that ruined our schedule. Despite my efforts… no matter how “busy” I was, I never saw the end of my team’s to-do list. Regardless of how much overtime we put in, we were still behind schedule. Still under pressure. Still stressed.

That was my situation back in 2005 when I worked in the Philippines as Head of Maintenance Execution for an offshore platform and onshore gas plant. Every week, we had a new ‘emergency’ that would throw everything up in the air. Not to mention the big backlog of general and safety-critical maintenance we had.

It was a working environment maintenance professionals would have nightmares about. Thankfully, it wasn’t a permanent situation. One of the main parts of our improvement plan was implementing Maintenance Planning & Scheduling. Slowly but surely, we created a more stable working environment.

We got control of our priorities, there were fewer emergencies, more proactive work, and less backlog. It gave us the breathing room we needed to tackle proactive work like conducting RCAs, improving our PM Program, and clearing our backlog. It took time and a lot of effort, but the transformation was significant.

Over the years, I learned that most professionals and organizations actually struggle with getting long-term results from implementing Maintenance Planning & Scheduling. And I found there are 4 common problems that’s stopping them from getting results:

PROBLEM #1:

Most plants don’t have an effective Maintenance Planning & Scheduling process

All too often, organisations are using Planning & Scheduling processes that are broken, flawed, or missing key steps. Here are a few examples:

- New work requests are poorly prioritised. Too much work that is not a priority breaks into the Weekly Schedule (if there is one). This “break-in” work is then planned on the fly, creating heaps of waste and inefficiencies.

- Jobs marked as “ready for execution” can’t be finished due to missing or incorrect parts. As a result, the work is delayed and the schedule goes down the drain. An effective planning & scheduling process ensures that any work that goes into the Weekly Schedule is 100% ready for execution (and that is not the same as ready for scheduling!)

- Many orgranisations can’t differentiate Planning from Scheduling. They think they are planning AND scheduling, but in reality, they ONLY schedule their work. And when your planners are busy scheduling, you will end up with a lot of poorly planned jobs leading to waste during execution.

Because of these gaps in their planning & scheduling process, these organisations are getting nowhere with their improvement efforts.

They still struggle with low productivity. Still stuck in the firefighting. Still dealing with excessive backlog. And still stressed.

And even if they DO have an effective process, another problem arises…

PROBLEM #2:

Most organisations don’t know HOW to effectively implement planning & scheduling

There are plants that have an effective Planning & Scheduling process on paper… they just never implemented it properly.

In fact, I’ve worked with several clients before who have said—

“Here’s the process that was written for us years ago. But we never really worked to it.”

When you then take a look at the process they mentioned, you’ll see that it’s not a bad process – certainly better than what they have at the moment.

They just didn’t know how to implement it properly.

That’s why having an effective process is in itself not enough. You need to properly implement it to get results for your organisation.

And in my experience, if you want to create long-lasting results, you need to apply Project Management and Change Management principles to successfully implement your Maintenance Planning & Scheduling process.

Without them, you will easily encounter resistance in implementation.

But the question is…

How do you know what project management & change management principles you need to apply? What is enough and when is it too much?

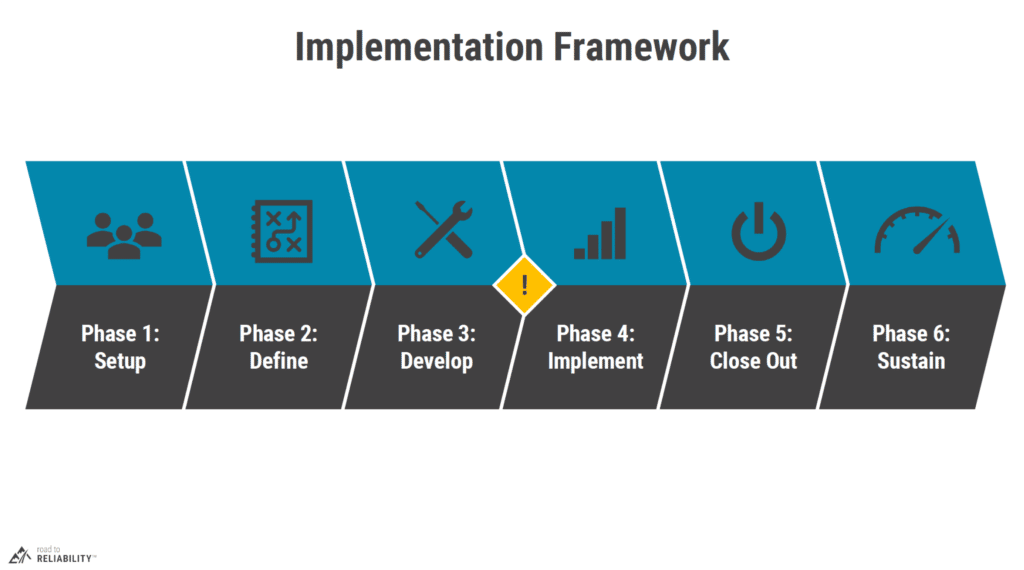

This is where the implementation framework inside the course provides huge value because it is based on clear project management & change management principles.

It has already been used in many organisations and countries, and is proven to work in the real world.

And what’s more…

The implementation of planning & scheduling is often led by a maintenance professional.

By their nature and because of their skillset, they tend to be technical people focused on solving technical problems with technical solutions.

Change management is about addressing unseen or future problems using mostly ‘soft skills’.

But these activities don’t align well with the strengths of most maintenance professionals. Experience shows that teams will often try to avoid or minimise these activities.

That is why our implementation framework is stage-gated to make sure all required activities are done (and verified) before you are allowed to the next part of the implementation.

A bit of pain, for a lot of future gains.

Now…

Even if you have an effective process, you have it documented and know how to implement it effectively… you will need a team that understands WHAT they need to do and WHY they need to do it.

That’s where the third problem comes in…

PROBLEM #3:

Most Planners and Schedulers aren’t formally trained

Let’s assume you have an effective Maintenance Planning & Scheduling process in place. To implement and execute this process, you need a competent team who knows the principles of Maintenance Planning & Scheduling.

The problem is, most planners and schedulers aren’t formally trained.

According to the data we received from our Planning & Scheduling Scorecard assessments, almost 50% of Planners and Schedulers have not been trained in Maintenance Planning & Scheduling. We’ve seen similar percentages when we’ve surveyed people:

So data clearly shows our Planners & Schedulers are not formally trained.

They simply learn on the job. As a result, they often learn bad habits and practices which are passed from one person to the next.

You see planners who mostly spend their day scheduling. Working hard at their desk, continuously rescheduling jobs in the CMMS, helping out the maintenance supervisor, and chasing parts for that emergency repair.

Because that is what is asked of them. That’s what’s expected. But it’s not what they should be doing.

They should be planning future work.

They should be out in the plant scoping and diagnosing work.

They should be discussing how to do future jobs with the supervisor.

That is how planners add value to a maintenance organisation. Because most planners and schedulers have not been properly trained, they don’t know these things. They don’t really know what they should be doing.

They don’t know WHY they should be doing them. And equally important they don’t know what work they should NOT be doing and why. Understanding the WHY is key to their success. People perform so much better when they understand WHY certain steps are required.

In fact…

Plenty of ‘veteran’ planners and schedulers who’ve had no formal training skip key steps in the Planning & Scheduling process because they don’t understand WHY they have to do these steps. I’ve seen this happen time and time again with my students and in my own experience as a maintenance manager. That’s why it’s important to formally train your planners and schedulers. But here’s where the last problem happens…

PROBLEM #4:

Traditional training isn’t as effective as it should be

Most Planning & Scheduling training courses nowadays are done using 3-day live webinars. The problem is, three days isn’t nearly enough to digest and understand everything you need to learn about Maintenance Planning & Scheduling.

It’s like drinking from a fire hose – you get a huge amount of information in a short amount of time. It’s difficult to absorb. And difficult to remember. In fact…

Research has shown that this type of short intensive training course results in—

- low levels of knowledge retention

- very limited change in the client organisations.

- And in general, pretty poor return-on-investment.

That’s because these types of training courses have no way to assess whether you’ve learned anything or not. There are no assignments. No exams. No feedback. They simply give you the information and leave you to figure out everything on your own.

Three months after the training, you will have forgotten most of what was covered in those courses. You have no chance to go back and review them. You can re-read the slides, and re-read your notes, but you can’t re-watch the presentations. And it gets worse…

Even if you trained a few individuals from your team using an effective and proven training program, it is not enough. You will not see any significant changes because you will encounter resistance.

For change to take place, you will need to create a culture of Maintenance Planning & Scheduling inside your organisation.

To create that culture, you need to train your ENTIRE team using a proven training program.

But most organisations avoid doing this because of how expensive and difficult it is to get a large number of people to attend a training program.

Not to mention the huge losses if that training program does not get you any return on your investment.

Now that you know about the common problems faced by professionals and organisations in Maintenance Planning & Scheduling…

Let me ask you…

Have you encountered these problems?

Are you unsure about your own Maintenance Planning & Scheduling efforts because you were never formally trained?

Are you tired of working overtime in reactive maintenance, only to find out that the work never stops and just keeps growing?

Have you tried looking for courses or solutions online, but can’t find the best one that actually guides you from theory to implementation?

Are you tired of information overload that is very common in most Maintenance Planning & Scheduling courses out there?

If your answer is YES to any of these questions, then I want to introduce to you…

PS100: Implementing Maintenance Planning & Scheduling online training course

This is a complete training course that teaches you everything you need to know about Maintenance Planning & Scheduling, and how to effectively implement it in your organisation. Unlike other Planning & Scheduling courses out there, this course will force you to think critically on how to apply what you learned specifically for your organisation through assignments, quizzes, and a final exam.

What truly makes this course valuable and unique is the Implementation Framework which is based on Project Management and Change Management Principles that you will learn inside Module 10.

This is perfect for:

- New Planners or Schedulers who were never formally trained in the role and want to fast-track their learning.

- Veteran Planners or Schedulers who have been in the role for a long time but know that their team can perform better in implementing Maintenance Planning & Scheduling

- Maintenance Technicians who want to work as planners but lack the necessary knowledge and training to advance in their careers

- Maintenance Supervisors who want to improve their team’s productivity, efficiency, and morale by creating a more proactive culture in their organisation

It took me 20+ years to distill my experiences and expertise into this course. Now, you get to learn everything in 10 weeks or less.

You don’t have to experience years of firefighting just to learn how to effectively implement Maintenance Planning & Scheduling. You don’t have to waste your hair strands and brain cells (like I did) to figure out what works and what doesn’t. And you don’t have to buy Planning & Scheduling courses ever again because everything you need is inside the course. You can learn Maintenance Plannng & Scheduling within 10 weeks or less if you put in the effort. You need to…

Here’s what you’ll learn

To make sure you learn what maintenance planning & scheduling is, how it creates value in an industrial environment, and how to successfully implement it in your organisation, we will teach you:

And so much more!

The Course Structure

The PS100: Implementing Maintenance Planning & Scheduling consists of 10 Course Modules with 48 Lessons totaling 14 hours of videos.

We’ll set you up for success. In this module, we cover course objectives and go into the details of exactly what you’ll learn and how we will work together.

In addition, I’ll give an introduction to the online learning management system. And introduce you to our support staff and where and how to ask for help.

In this module, we start the real work. After a brief exploration of the role of maintenance in asset-intensive industries, we’ll explore why we need planning & scheduling.

We’ll cover the increase in productivity and what that means for the bottom line of your organisation. But we’ll also explore other key benefits of planning & scheduling that are less tangible like workforce motivation and safety.

We will also touch on some critical characteristics of maintenance work that influence how we set up a successful maintenance planning & scheduling process.

- How waste occurs in the execution of maintenance so you understand how planning & scheduling improves productivity.

- Understand the value and benefits that planning & scheduling will bring to your organization so you can effectively build a business case.

- Learn to treat planning & scheduling as a business process so that your improvements are sustained in the long term.

This is about work being initiated and prioritised. Fail to get this right and you’ll continue to chase your tail and will not get out of the reactive maintenance model.

Most organisations don’t realise how critical this step is. Most managers and supervisors don’t want to spend the time getting this right.

In this module I will explain why you don’t want to be making that mistake and why putting a lot of effort into creating quality work requests and prioritising them properly is so critical to your success.

And in the last lesson, we’ll touch on some KPIs that you can use to measure your success.

- Understand the importance of high-quality and well-prioritized work requests so that you give enough attention to this step in the process.

- Understand what makes a quality work request so that new work requests are not approved with built-in delays or sources of waste.

- How to prioritise work requests using RIME or RAM prioritization so that you can break out of a reactive environment.

Module 4 is all about maintenance planning, why it is important, and the 6 Maintenance Planning Principles that underpin a sound maintenance planning process.

We’ll talk quite a lot about roles & responsibilities because this is where many organisations go wrong. They burden their maintenance planners with work that should be done by others and in doing so they never reach the productivity improvement they were aiming for.

We’ll also discuss the level of detail that is required in a maintenance work order, what makes a good ‘work pack’ and we’ll touch on common mistakes and some useful KPIs.

- Understand the importance of maintenance planning so that you can effectively explain it to others in your organisation.

- Learn to see what good maintenance planning should look like so you can identify the gaps in your current practices.

- Understand the importance of keeping your maintenance planner focused on future work so you achieve the full benefits planning & scheduling can bring.

- Realise planning is all about continuous improvement so that you don’t get stuck aiming for perfection.

This is a step in the planning & scheduling process that is not often talked about, but it’s key to your success.

Once the work is planned, all materials are ordered, and purchase orders have gone out for external services you need to keep an eye out on when vendors are available, when materials will arrive at the site, etc.

And when that’s all in place, you need to flag the planned work in your CMMS as ‘Ready for Execution’ as a handover point to the Scheduler.

- Understand that “Fully Planned” is not yet “Ready to Execute”. It is important to understand this difference and make sure your planning & scheduling process incorporates this step effectively.

- Manage your backlog of work that is in your CMMS using various “buckets of work”. Having an effective process for managing backlog or outstanding work is essential even if you do not have a huge amount of outstanding work.

Module 6 is all about scheduling. We’ll talk about how scheduling is different from planning and why you need both.

We’ll discuss 5 basic scheduling principles including why you need to schedule for a Frozen Week. how to build up your Weekly Schedule. And we’ll delve into capacity planning plus we’ll talk about some basic scheduling techniques and concepts.

As usual, our last lesson in this module will cover KPIs in this case those KPIs that you can use to drive your scheduling process, for example, Weekly Schedule Compliance.

- Understand the importance of maintenance scheduling so that you can effectively explain it to others in your organisation.

- Know what good maintenance scheduling should look like so you can identify the gaps in your current practices.

- Understand how to use long-term scheduling to drive overall productivity and minimise equipment.

- Learn how to use the “Magic Three” performance metrics to analyse and improve your planning & scheduling performance.

Module 7 is all about executing the maintenance work that has been planned and scheduled. This is the core of the process and a lot of what we do in planning & scheduling is to drive efficiency in this part of the process.

We’ll focus extensively on the role of the maintenance supervisor. We’ll discuss in detail how you need to manage Emergency Work. And we’ll touch on how you should be dealing with Emergent Work, the work you discover whilst doing a job.

- Understand the role of the Maintenance Supervisor so that execution is as efficient and effective as it should be

- Understand how to make simple improvements to improve quality in maintenance and significantly reduce the likelihood of future failures

- Learn how to deal with Emergency Maintenance and Emergent Maintenance so that you don’t ruin productivity

Module 8 covers the close-out of work. This is where we capture everything that went well and the things that didn’t go too well.

We provide feedback to the planner in terms of planning quality, materials, etc. and we capture technical history in the CMMS so the reliability engineers can use that information in their continuous improvement programs. We’ll also discuss how this links into your Defect Elimination and Root Cause Analysis processes.

The secret to successful planning & scheduling is a continuous improvement loop and that relies on the proper close-out of work and high-quality feedback.

- Explain the minimum requirements of close-out so that you end up with an effective process

- Discuss the feedback loop from the execution crew to the planner so that individual job plans can be improved quickly

- Discuss the basic requirements for closing out a job and recording technical history so that we can review and improve our performance

Module 9 is all about making things better and better or in other words: Continuous improvement and how to build that into your business and your work processes.

We’ll delve into using KPIs to drive performance and the limits to what KPIs can do for you. We’ll talk about the need to have a ‘process owner’ who conducts annual process ‘audits’ and the value of GEMBA walks.

In Lesson 4 of this module, we’ll touch on a contentious subject – measuring wrench time. How to do it, when to do it and when not.

- Learn the continuous improvement loops in our planning & scheduling process so that you can effectively embed these in your organisation.

- Use several tools that we will provide you so that you have more formal and structured methods to improve your performance.

Module 10 is where this course is completely different from all the other planning & scheduling courses out there. In this module, we will give you a tried and tested process to implement planning & scheduling in your organisation.

We’ll cover the business case, change management basics, setting up your project team for success, and the need for coaching. Each lesson comes complete with practical tools and techniques that are proven to work when it comes to implementing planning & scheduling in a real business environment.

- Ensure you understand the importance of change management when implementing planning & scheduling so that the changes you implement will be sustainable over time.

- Provide you with a practical, proven framework to implement planning & scheduling so that you are set up for success and can avoid the mistakes that many other organisations make.

- Introduce you to the tools & templates provided to make implementation easier so that you can focus your effort on the actual implementation.

Here’s what my students have to say

“A really valuable course. The videos are really good, and Erik explains everything with a wealth of knowledge.”

Dan Stuart

Maintenance Delivery Lead at Petrofac UK

“A Breath of fresh air”

“… his newly created Maintenance and Scheduling course was a breath of fresh air…The content he provides is very comprehensive and easy to understand. One of the most useful chapters is how to implement the program, a topic often missing in many courses and trainings…I highly recommend it to any person or company endeavouring to advance their company’s maintenance efficiency and productivity.”

Martijn Hadders

Manager Global Maintenance & Asset Management at Henkel

“Worth every penny”

“An excellent course worth every single penny. I wholeheartedly recommend it to all practitioners, beginners and mature maintenance or operations managers alike, as everyone can benefit from it”

Andrej Androjna

MQuantum Consulting at Slovenia

All the resources and templates you need to succeed

We made sure that you get value during your learning journey inside the course. That’s why apart from the training course itself, you will also get access to the following resources.

Q&A during office hours

Discussion Forum

Have a productive conversation with other practitioners inside our discussion forums. Ask any question, or read other people’s questions that have already been answered.

Translation to other languages

Certificate of completion (PDF)

Proof that you have accomplished an intensive training in Maintenance Planning & Scheduling from an accredited course.

Digital Credential

SMRP Recertification credits.

All templates required to document the Planning & Scheduling process

Complete set of change management & implementation tools

Course slides (PDF), Transcript (PDF), and Audio (MP3) of all lessons

How much will it cost?

If you’re going to enroll in a typical Planning & Scheduling course, you’ll spend around $1,200 to $4,000 for a three to five-day live webinar training.

But you won’t get all the tools and templates that you need. You won’t get an implementation framework. You won’t have regular access to somebody who you can ask about the implementation process. You won’t have lifetime access so you can’t go back to review the lessons. And you’ll have to learn everything within the space of a few days.

But as part of our mission to create thousands of reliable plants around the world, we’ve made this training course accessible and affordable for you and your organisation at the one-time price of $1,495.

Once you click the button, you’ll be redirected to a secure payment page. You’ll be asked to fill in your email address and pay via PayPal or Credit Card.

After payment is confirmed, you’ll get INSTANT access to the learning platform where you’ll find all of the course videos, tools and templates.

Your login details for the learning platform will be sent to your email address. And to make this decision even easier for you…

You’re protected by our

30-day Money Back Guarantee

I’ve had hundreds of students love the course. That’s why I’m confident that you’ll love it too. That you’ll get your money’s worth.

But if you’re not satisfied with what you see inside, I’ll give you your money back, no questions asked.

Think about it…

If you enrolled in a live Maintenance Planning & Scheduling webinar… and 3 hours later, you decided that you don’t like the program… could you walk up to the presentor/teacher and ask for your money back?

… you could… but you would certainly not get a refund.

But with this guarantee, you can try the course for 30 days, and if you decide that you don’t like my online course, you can simply ask for a refund. As long as:

- You have completed the first 3 modules – this is to make sure students have actually done a decent part of the course and have given it a chance

- You have not completed the course – this is to ensure people don’t get free training

- You request the refund within 30 days of purchase

That’s how much I believe in this training program.

Does that sound more than fair?

If you think it is, then click the button below to start your journey to mastering Maintenance Planning & Scheduling.

Planning & Scheduling FAQs

© 2018 – 2022 R2 Reliability Pty Ltd | Privacy Policy | Terms and Conditions

Contact us at [email protected]